Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

How to fit a Centre Bearing

What is a Centre Bearing?

What is a Centre Bearing?

The Centre Bearing is designed to support the central prop shaft when a two-piece shaft is fitted. It has a large rubber mounting and bearing fitted inside a metal cage which is attached to the chassis.

The whole centre bearing mount is fitted to the front section of the rear or rear prop shaft and retained by the flange and central nut.

Why do I need to replace the Centre Bearing?

Prop shaft centre bearings fail over time. The bearing itself can become noisy or the rubber bushing can become soft, perished or even split causing vibration or even knocking noises. They can also seize up if the rubber hardens.

How do I fit the bearing?

How do I fit the bearing?

- Firstly you need to remove the prop shaft which is done by simply undoing the central flange nut. The flange has a ‘spline’ which are ridges that mesh to the main shaft. Before removing it make a mark so you can align both flange and main shaft so that it goes back on in the same position.

- The complete centre bearing can then slide off the prop shaft.

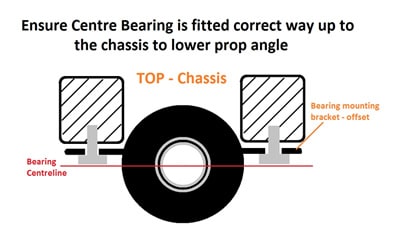

- When refitting it there is only one way up that the bearing will fit. Some models have bearings like the one above which has a metal cage with two tabs that bolt to the chassis, these tabs are not central to the bearing, you must ensure the bearing is fitted the correct way to the chassis to reduce the overall angle of the shaft down to the rear diff, fitting it incorrectly will increase the angle and cause excess strain on both the new bearing and indeed the Universal Joints (UJ's).

- Once fitted the very nature of the mount is a rubber support, therefore you will always have some movement within the rubber mounting.

If a bearing still keeps failing, what could be the cause?

There could be several reasons for early failure not related to the bearing itself:

- Check that no oil or contaminants are on the rubber, this could cause it to soften the material

- Check the bearing is fitted the correct way up to the chassis - it could easily be fitted either way up, but only one way is correct.

- Check for any play in the universal joint, this could cause vibration that may not be felt.

- Check that the shim washer (if fitted) is in place between the flange and bearing, this spaces the flange away from the bearing itself and failure to have it fitted correctly can cause the bearing to overheat through friction. This is something that is often missed on assembly.

You can view our Centre Bearings and Mounts